Mechanical Assembly

Keystone assembles complex box builds, sub-assemblies, and unique components at our state-of-the-art facility, adhering to ISO9001:2015 standards. Parts are tracked using barcoded work orders ensuring 100% traceability of materials and parts from vendors.

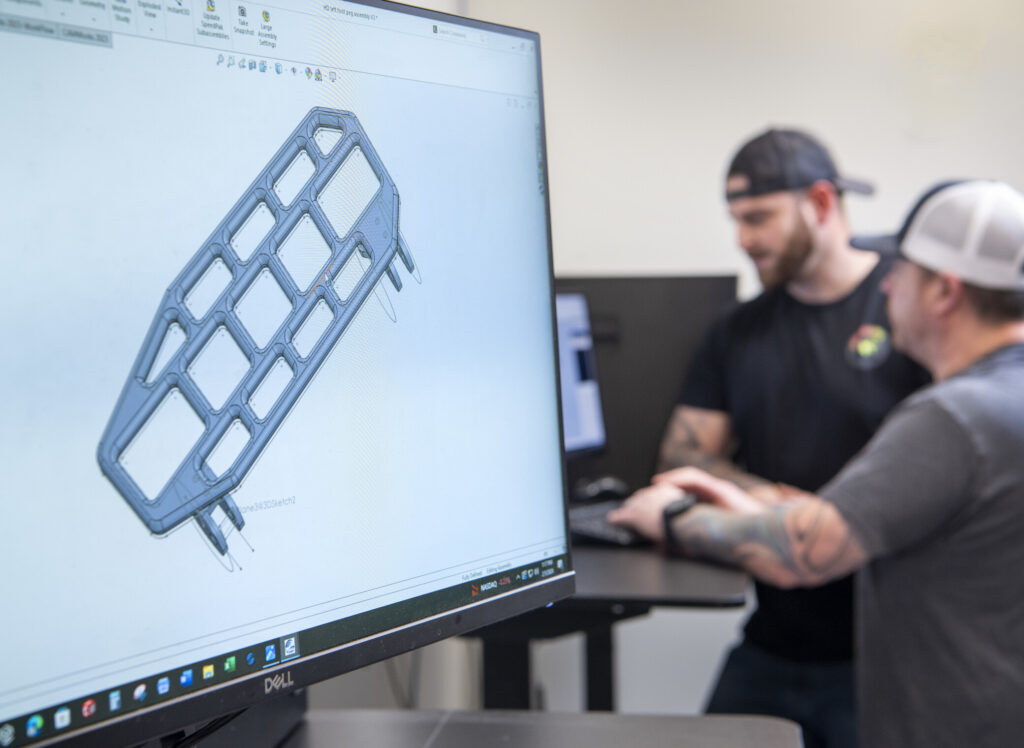

Design for Manufacturability (DFM)

Because efficient production assemblies – and fast time to market – are based on part design, Keystone works with your engineering team to review designs before beginning production.

With a keen eye for catching tolerance stack-ups, we ensure your complex box-builds and multi-part sub-assemblies have zero gaps, misalignments, or other issues. Our Team can suggest design changes to improve manufacturing processes that lower costs and reduce delivery time.

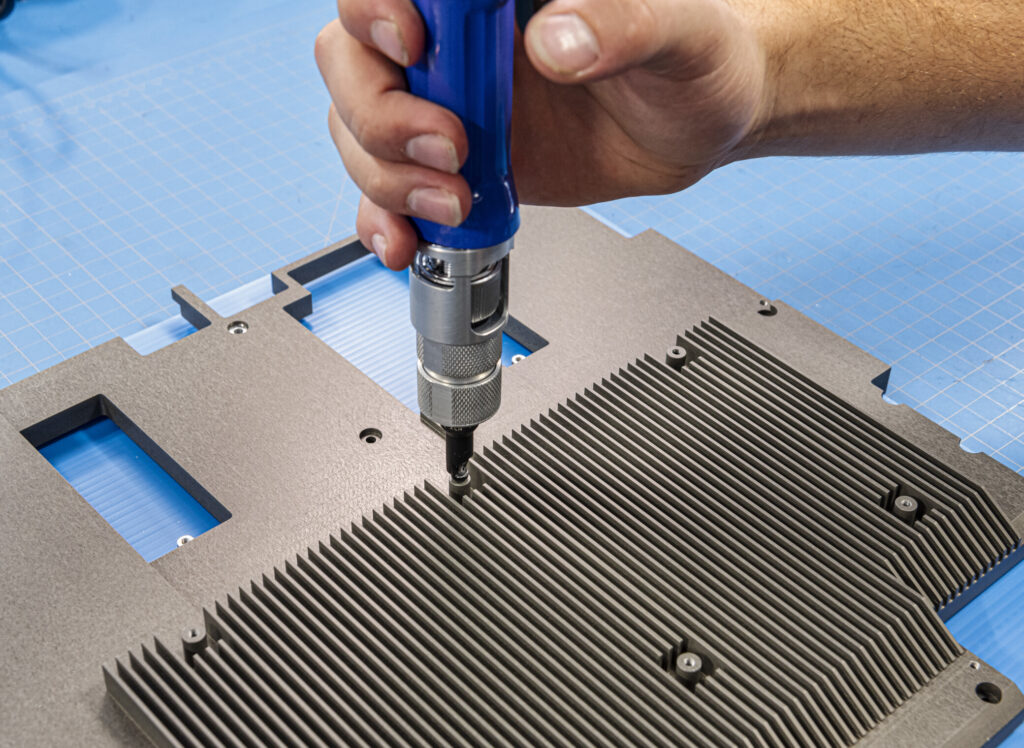

Multi-Part Assemblies

Keystone specializes in assembling complex parts and box assemblies, which are installed in control units for missiles, military drones, industrial machinery, and non-invasive medical devices.

Full service production

Keystone is a one-stop shop combining in-house machining and assembly techniques with a wide array of approved vendors including, but not limited to, water jetting, sheet metal, screw machine, plating, painting, and welding.

Need help with a project?

Whether short runs, high-volume production, or start-to-finish assembly, we’re ready to meet your needs. Depending on part complexity, we can turn your job around within days of your order.